Wahaso was a great fit for me. I have been a sales and marketing executive for my entire career, working in brand management for large packaged-goods firms. I even taught marketing at Keller Graduate School of Management in Chicago for several years, in addition to consulting. Before Wahaso, I had been looking for a new business opportunity that would let me apply my understanding of business strategies and marketing. At the same time, I’m a “green” guy interested in protecting the environment through conservation of energy, water, and other resources. I love leading a company that is positioned to make a significant impact on reducing the use of municipal water resources for nonpotable applications like toilet-flushing and irrigation.

Wahaso was a great fit for me. I have been a sales and marketing executive for my entire career, working in brand management for large packaged-goods firms. I even taught marketing at Keller Graduate School of Management in Chicago for several years, in addition to consulting. Before Wahaso, I had been looking for a new business opportunity that would let me apply my understanding of business strategies and marketing. At the same time, I’m a “green” guy interested in protecting the environment through conservation of energy, water, and other resources. I love leading a company that is positioned to make a significant impact on reducing the use of municipal water resources for nonpotable applications like toilet-flushing and irrigation.

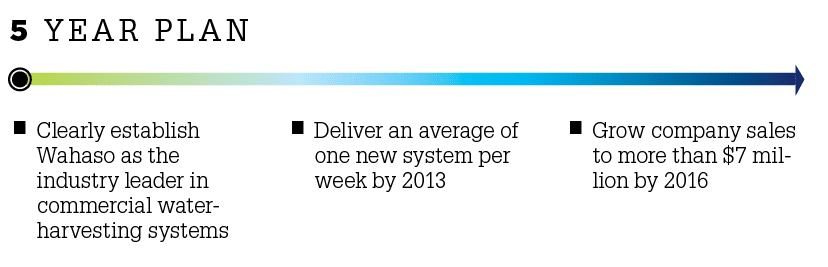

When my partner, Stuart Bailin, proposed a company focused on water-harvesting systems, I did some research and discovered that there were no firms in the market positioned directly at the commercial sector. With my familiarity with green-industry trends, especially around LEED certification, I was convinced there was a market opportunity for just such a firm, with high-growth projections. We have enjoyed a first-to-market advantage in providing solely business-to-business services. We harvest rainwater, stormwater, and greywater for irrigation, toilet flushing, cooling-tower makeup, and other uses.

In our client-acquisition model, a critical step is the scoping stage. This begins with establishing a relationship with the client and consulting on the building’s possible sources and uses of onsite water. We must provide credible data and analysis for clients to feel confident that our recommended system will meet budget and water-savings goals. We have been working to enhance our scoping tools and deliverables so that we can quickly offer clients the information they need to approve a proposal.

For example, water storage is often the most expensive component of our systems. Therefore, we developed a proprietary tool that models different storage capacities, using six years of recorded daily rainfall in the project’s location. This takes into account historic periods of drought or excess rainfall with different options for storage capacity, to determine the point of diminishing returns for capacity size. We deliver that data in an impressive report that our clients can present to the building’s stakeholders. And while technical schematics are great for the building’s engineers, we write a system concept in plain English that all members of the project can relate to.

For example, water storage is often the most expensive component of our systems. Therefore, we developed a proprietary tool that models different storage capacities, using six years of recorded daily rainfall in the project’s location. This takes into account historic periods of drought or excess rainfall with different options for storage capacity, to determine the point of diminishing returns for capacity size. We deliver that data in an impressive report that our clients can present to the building’s stakeholders. And while technical schematics are great for the building’s engineers, we write a system concept in plain English that all members of the project can relate to.

Each project is unique, which has meant that each design requires custom engineering and new learning for our production crew. Our strategy is to “productize” key subcomponents of our systems so that they are standardized and marketable at the lowest possible cost. A good example of productizing is the chlorination system we use to sanitize water. Our former approach used expensive components from other manufacturers. It was adding over $20,000 to a project’s cost, which was just too high. So our engineering team created the Wahaso WCC 100 Calcium Hypochlorite System, which automatically monitors and controls residual chlorine levels in treated water. Not only is the design simpler and more effective, but it has reduced the subcomponent cost by over 65 percent. Now we can market it as a unique Wahaso feature, and its proprietary design makes it difficult for competitors to break our specification for a project.

We are in a new and evolving industry, and many of our systems are the first of their kind for these applications. The components we employ—the filters, pumps, sensors, etc.—are familiar to the greater water-handling industry, but their application for water reuse is unique to our designs. We have learned the hard way what works and doesn’t work well in this emerging market. The good news is that since we are a market leader, we have a head start with our field experience over new competitors. By the time they learn these lessons, we hope to be even further ahead.