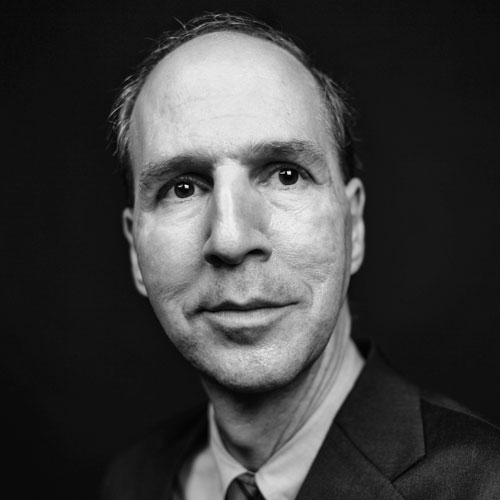

New technology makes tracking results at SRS Distribution easier than ever, thanks to Robby McDonald, who’s ensuring that all aspects of business are running as smoothly as possible. As chief information officer and chief marketing officer of SRS Distribution, a roofing supply company, McDonald gets to challenge the company’s technological capabilities and expand its possibilities. Figuring out where to store all of the company’s data is a major project that McDonald and his team are still working on to make sure all the information is kept in one place.

“First we had to decide on the right technology to use—whether we go with Microsoft and its data warehousing product or Oracle’s data warehousing product,” McDonald says. There are other options, but McDonald says that Microsoft and Oracle are the two major ones used by industry leaders.

That decision was made easier by the fact that SRS Distribution already works mostly with Microsoft products. “We’re pretty much a Microsoft shop, so that was really the direction we felt would be best for what we’re doing today to maximize our license agreement with Microsoft,” McDonald says. “The second choice was whether we go on premise or go out into the cloud. We started on premise and now we are looking to move that data warehouse into the cloud.”

In order to stay competitive, it’s important for a business to be able to measure its performance, and McDonald says that was the first thing they decided to focus on once they had set up the new data warehouse.

“Since we are a private equity firm, EBITA [earnings before interest, taxes, and allowances] is really a major focus for the organization,” McDonald says. “We have every single one of our branches ranked from 1–152. All of our sales team is ranked 1–N, so the numbers and the way the company is performing are always at the front of our minds with everything we work on. So we chose to have the finance information as the first thing we got into the data warehouse.”

Accomplishing all of this meant they had to put all their ERP (enterprise resource planning) data out of a third-party accounting and business management software, written by DMSi software called Agility.

“Once we were able to get all our ERP data into the data warehouse, we were able to start recreating all the financial reports we had been producing via Microsoft Excel and other platforms,” McDonald says. “Then we could start showing our managers and vice presidents all the information from a financial perspective.”

But the new data warehousing system is just one upgrade McDonald has brought to the company. Like everyone else looking to get ahead of the competition, McDonald has turned SRS Distribution’s sights to social media as part of our overall digital communications strategy.

As a roofing supply company, SRS Distribution’s contractors want to know where hail is going to hit or has hit. Together with their weather partner, Core Logic, SRS Distribution has started experimenting with social media to get the information that their contractors need.

“Generally, the first thing someone does when hail hits is go outside, hold it in their hand, and snap a picture and either tweet it to someone or post it on Facebook,” McDonald says. “Or there’s video of hail falling, so we trigger on certain keywords and then combine that with the weather data we’re getting from Core Logic to provide our contractors specific information about the areas that hail has fallen to help the contractor determine if this is a viable area to go canvas for hail.”

As always, it’s all about timing, and by using the immediacy of social media, SRS Distribution gives its contractors that edge.

“Generally, we can get our contractors out there two to three days before the big rush of contractors that go in and start canvassing an area,” McDonald says. “If you can get in their early and fast, then you have a much higher probability of winning that job.”

This project is still in the testing phase, but it’s one way the company is looking forward to stay competitive in the future, according to McDonald.

SRS Distribution also uses technology to make sure everything goes smoothly when they make a delivery to a contractor.

“We have a module in all of our trucks that tracks its location using GPS,” McDonald says. “That system also has on-demand routing, which will help them route the best way for these deliveries to be made.”

Additionally, they have started using technology proactively to provide proof of delivery documenting any preexisting damage.

“We have an application where we take pictures of everything for that delivery,” McDonald says. “So we’ll take a picture of the address, the shipping list, the driveway, the mailbox, anything that may be wrong with that particular delivery so it doesn’t come back on the contractor or on us. Then we take pictures of the actual product as proof of delivery.”

This tracking also allows them to help their customers. “We can give them a statement at the end of that tracking period that shows everything they’ve earned through that program with that vendor,” McDonald says. “So it helps them really go get money they’ve never had before because we make it so easy for them.”