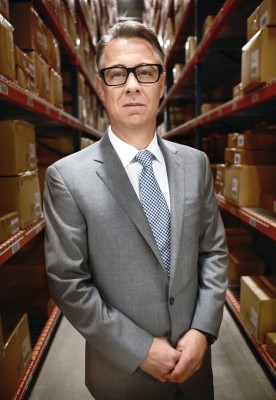

Executive VP of Supply Chain

Company: Carter’s

Location: Atlanta, GA

Vitals: While attending the University of Georgia, Chris Rork ran his own small business creating college-licensed apparel. Upon graduation, he decided to stay in the field, crisscrossing the world, working for everyone from Ralph Lauren and Levi Strauss & Co. to Cyrk.

What do you think it is that has made you successful in this industry?

Chris Rork: In every role, I’ve always tried to be cognizant of the merchant side of the business, because that’s what helps you understand the customers and consumers. I’ve joked I’m a merchant trapped in a supply chain body. It’s good to be adaptable. I’ve had so many different experiences within Carter’s, from sourcing and product development to inventory and distribution. Throughout my career, I’ve focused on the inventory management side of the business and learning to understand how it impacts profitability and brand equity. The variables are always changing, so it’s a constant challenge.

Managing a company’s supply chain is a vital task. What are the biggest challenges you’re up against each day, and how do you navigate around these issues?

Rork: There are so many variables that are entirely out of your control. For Carter’s, there are more than 400,000 people that make our supply chain run, and if any one of those people falls short, it can disrupt our business. So again, while you can’t necessarily directly control all of these things, sound planning and an understanding of what can go wrong in advance can prevent issues. And if that fails, have a good plan B. I have a saying: “Late deliveries happened six-months ago, they just manifested themselves now.”

How do you make a successful plan to avoid such scenarios?

Rork: I’ve found that you can stay on top of things by being well-informed when it comes to macroeconomics and current events. Many of the conversations among our supply chain team may sound more suited for a trading floor. We’re discussing cotton crops, foreign currency, energy, labor indices, and country elections. We use that intel to make smarter decisions. There are never any boring days.

What trends in retail are shaping how you approach supply chain management?

Rork: Our brands are based on value and we are constantly looking to drive out cost in the supply chain by eliminating inefficiencies. Some of the current trends, like fast fashion, are not really our model, though we also strive to get the highest level of productivity out of our inventory.

Tell me about the company’s move into direct-to-consumer products.

Rork: We’ve been around since 1865, and we’ve been deeply rooted in wholesale for most of our existence. Over the past 10 years, we have become more balanced in multichannels. Our distribution centers were set up as case in, case out, and inventory was “cook what you book.” A lot has changed since then. Forecasting is very critical to us, and it’s important for us to maintain the value we provide to the customer. How to make our inventory more productive and spread out over multiple facilities gives us a better advantage.

What are some of the goals for Carter’s moving forward?

Rork: Continuing inventory productivity through our robust pipeline. We opened Carter’s Global Sourcing last year as a compliment to our agent relationship with Li & Fung. We are diversifying the countries from which we source from, while also reducing our lead times. Lastly, I want to continue looking at how to build a more sustainable supply chain, how to provide great efficiency, more profits, and have less of an environmental impact.